Description of Biaxial Polypropylene Plastic Geogrid

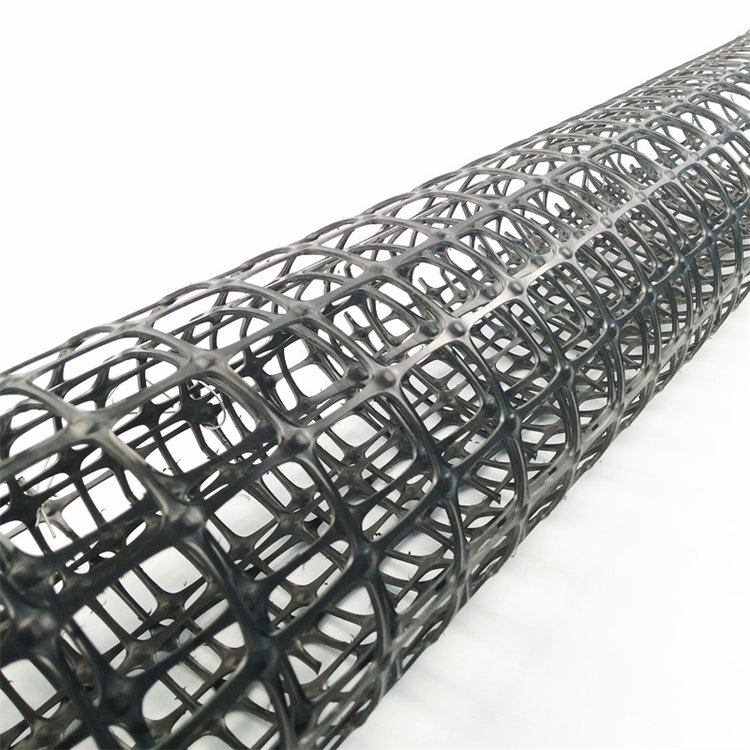

Bidirectional plastic geogrid is made of high molecular polymer through the process of extrusion, plate forming and punching, and then stretched longitudinally and transversely. The material has great tensile strength both longitudinally and transversely. This structure can also provide an ideal interlocking system for more effective force bearing and diffusion in the soil, and is suitable for large-area permanent bearings. Foundation reinforcement.

Application of biaxially stretched plastic geogrid

1. Increase the bearing capacity of the road (foundation) and extend the service life of the road (foundation).

2.Prevent the road (ground) surface from collapsing or cracking, and keep the ground beautiful and tidy.

3.Prevent cracks in culverts.

4.Strengthen and reinforce soil slopes to prevent soil erosion.

5.Reduce the thickness of the cushion layer and save costs.

6.Support the stable greening environment of slope grass planting net mat.

Construction method

Excavate the foundation bed, set up a sand cushion (the height difference is no more than 10cm), roll it into a platform, and lay the grid. The longitudinal axis should be consistent with the main stress direction, with a longitudinal overlap of 15-20cm and a transverse overlap of 10cm. Bind it with plastic tape, and fix it to the ground with U-shaped nails every 1.5-2m on the laid grid. The laid geogrid should be backfilled with soil in time. The number of laid geogrid layers depends on the technical requirements.

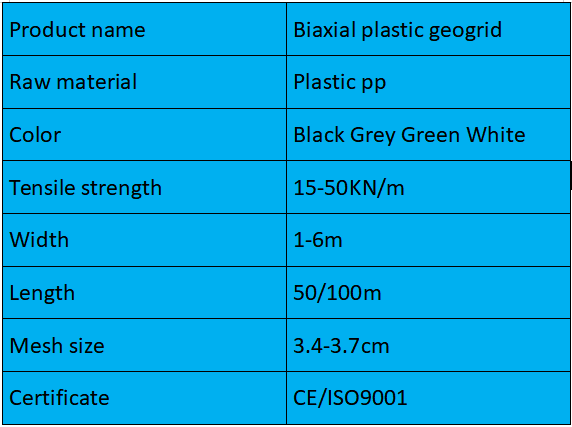

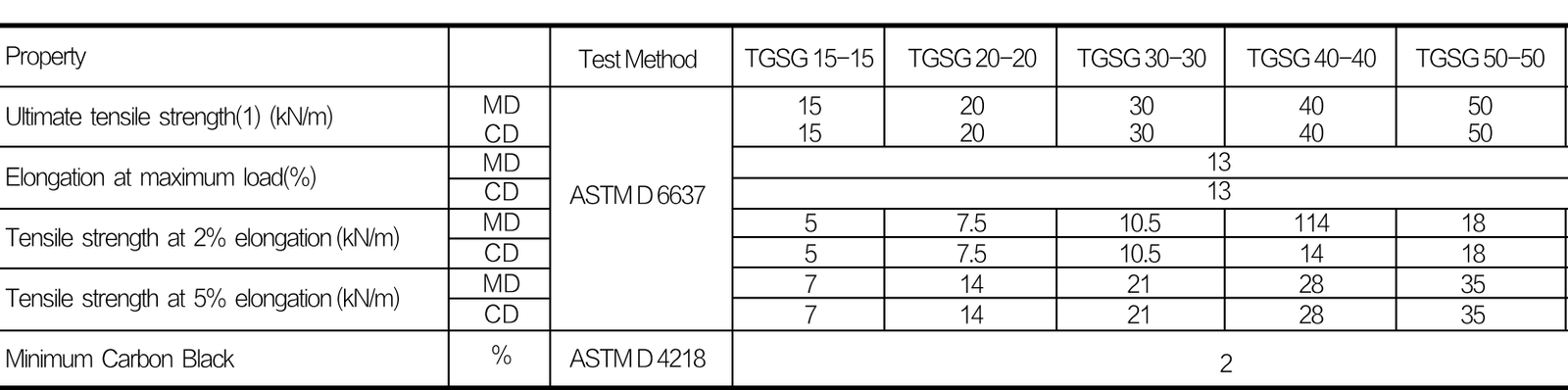

Specifications and performance parameters

Reviews

There are no reviews yet.