Description of geotextiles

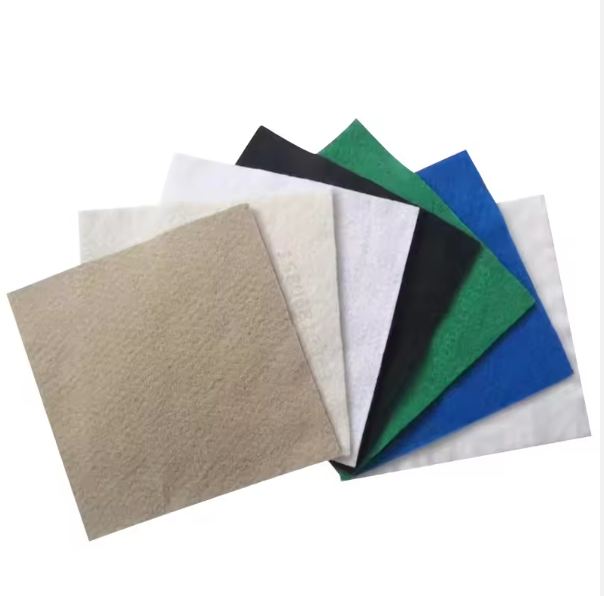

Geotextile is a water-permeable geosynthetic material made of synthetic fibers through needle punching or weaving. Geotextile is one of the new geosynthetic materials. The finished product is cloth-shaped, generally 4-6 meters wide and 50-100 meters long. Geotextiles are divided into spinning geotextiles and non-woven filament geotextiles.

Feature:

1. High strength , low deformation.

2. Durability: steady property, not easy to resolved, airslaked and keep the original property long term.

3. Anti-erosion: anti-acid, anti-alkali, resist insects and mould.

4. Permeability: Geotextile can control the sieve size to retain permeability.

Application:

Nonwoven Geotextile is widely used in road construction. It strengthens soil by increasing its tensile strength.

1.Erosion control: Nonwoven geotextile is used to prevent soil erosion on slopes, embankments, and shorelines. They provide a barrier that stabilizes the soil and prevents it from being washed away by water.

2.2. Road construction: Nonwoven geotextile is used in road construction to separate the subgrade from the base and to reinforce the soil. They help to improve the strength and stability of the road, as well as prevent the mixing of different layers of soil.

3.Filtration: Nonwoven geotextile is used in filtration applications to separate different materials and allow the passage of fluids. They are used in drainage systems, dewatering processes, and environmental protection projects.

4.Landscaping: Nonwoven geotextile is used in landscaping projects to separate different layers of soil, prevent weed growth, and provide stability to the soil. They are commonly used in gardens, parks, and other green spaces.

Construction and laying of geotextile

1.Use manual rolling, the cloth surface should be smooth, and appropriate allowance for deformation should be left.

2.The installation of filament or short-filament geotextiles usually involves overlapping, sewing and welding methods. The width of stitching and welding is generally more than 0.1m, and the width of overlap is generally more than 0.2m. Geotextiles that may be exposed for a long time should be welded or stitched.

3.Sewing of geotextile:

All stitching must be done continuously (e.g. spot stitching is not allowed). Geotextiles must overlap by a minimum of 150mm before overlapping. The minimum stitch distance from the selvedge (the exposed edge of the material) is at least 25mm.

Sewn geotextile seams consist of a single row of wired lock chain stitches. The thread used for suturing should be a resin material with a minimum tension exceeding 60N, and have chemical corrosion and ultraviolet resistance that is equivalent to or exceeds that of geotextiles.

Any “missed stitches” in the sewn geotextile must be re-sewn in the affected area.

Appropriate measures must be taken to prevent soil, particulate matter or foreign matter from entering the geotextile layer after installation.

The overlap of cloth can be divided into natural overlap, seam or welding according to the terrain and use function.

4.During construction, the geotextile on top of the geomembrane is naturally overlapped, and the geotextile on the top layer of the geomembrane is seamed or hot air welded. Hot air welding is the preferred method for connecting filament geotextiles. That is, a hot air gun is used to instantly heat the connection between two pieces of fabric to a molten state, and a certain external force is immediately used to firmly bond them together. . When thermal bonding cannot be performed in wet (rainy and snowy) weather, geotextiles should adopt another method – suture connection, that is, use a special sewing machine to perform double-thread suture connection, and use sutures that are resistant to chemical ultraviolet rays.

The minimum width is 10cm when sewing, 20cm when naturally overlapping, and 20cm when hot air welding.

5.For seams, use sutures of the same quality as geotextiles, and sutures made of materials that are more resistant to chemical damage and UV exposure.

Precautions for geotextile installation and construction:

1.Geotextile can only be cut with a geotextile knife (hook knife). If it is cut on site, special protective measures must be taken for other materials to prevent unnecessary damage to the geotextile due to cutting;

2.While laying the geotextile, all necessary measures must be taken to prevent damage to the underlying material;

3.When laying the geotextile, care must be taken not to allow stones, large amounts of dust or moisture, or other substances that may damage the geotextile, block drainage channels or filters, or cause difficulty in subsequent connections, to enter the geotextile or geotextile. underneath the cloth;

4.After installation, conduct a visual inspection of all geotextile surfaces to identify all damaged areas, mark them and repair them to ensure that there are no foreign objects on the surface that can cause damage, such as broken needles and other foreign objects;

5.The connection of geotextiles must comply with the following regulations: Under normal circumstances, there can be no horizontal connections on the slope (the connection must follow the contour of the slope and not intersect with it), except for repairs.

6.If sutures are used, the sutures must be made of materials that are the same as or exceed the material of the geotextile, and the sutures must be chemically resistant to ultraviolet rays. There should be obvious color difference between the suture line and the geotextile to facilitate inspection.

7.Pay special attention to the seams during installation to ensure that no dirt or gravel from the gravel cover gets into the middle of the geotextile.

Reviews

There are no reviews yet.