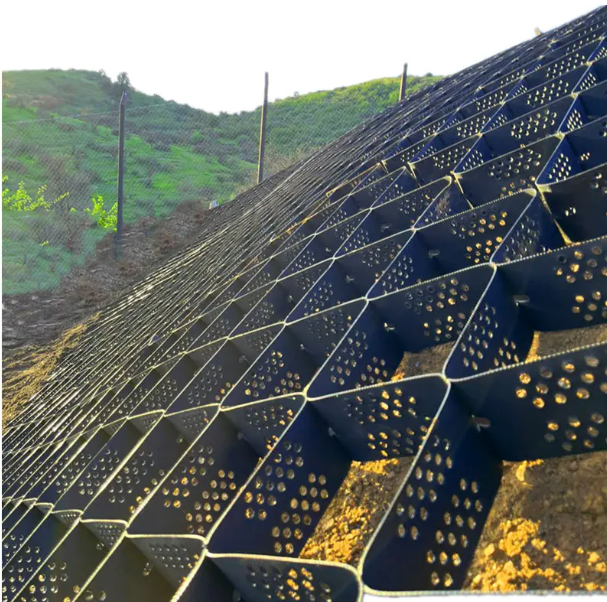

Description Of Road Construction HDPE Geocell

Road Construction HDPE Geocell is a perforated cellular confinement system engineered from HDPE sections for maximum performance. It is designed to improve soil stabilisation, erosion control, and increase load support.HDPE Geocells available in a number of depth and cell opening combinations. HDPE Geocells supplied in a folded configuration that minimises transport costs to site yet can be readily expanded on site for very quick installation. HDPE Geocell has been perforated to ensure that each cell does not become water saturated during use.

Specification Of Road Construction HDPE Geocell

| Product Type | Height (mm) |

Welding Distance (mm) |

Thickness (mm) |

Tensile Strength of Welding Points (N/cm) | Tensile Strength of Connection of Cells (N/cm) | Tensile Strength of Yield of Each Sheet (Mpa) |

| Smooth and Not Perforated | 50≤H≤250 | 330≤A≤1200 | 1.0-2.0 | ≥100 | ≥120 | ≥20 |

| Smooth and Perforated | 50≤H≤250 | 330≤A≤1200 | 1.0-2.0 | ≥100 | ≥120 | ≥20 |

| Textured and Not Perforated | 50≤H≤250 | 330≤A≤1200 | 1.0-2.0 | ≥100 | ≥120 | ≥20 |

| Textured and Perforated | 50≤H≤250 | 330≤A≤1200 | 1.0-2.0 | ≥100 | ≥120 | ≥20 |

| Remarks: This is a basic technical specification. All the above technical parameters can be reached according to customer’s requirement and other special standard can be carried out by agreement or contract. |

||||||

Application Of Road Construction HDPE Geocell

1.Processing half-filled and half-excavated roadbed

When building an embankment on a slope with a natural slope steeper than 1:5, steps should be dug at the base of the embankment. The width of the steps should not be less than 1M. When the road is built or rebuilt in stages and widened, the connection between the old and new roadbed fill slopes should be opened. When digging steps, the width of high-grade highway steps is generally 2M. Geocells are laid on the horizontal surface of each step, and the facade side reinforcement effect of the geocells itself is used to better solve the problem of uneven settlement.

2.Roadbed in sandy areas

The roadbed in windy and sandy areas should be mainly low embankment, and the filling height is generally not less than 0.3M. Due to the professional requirements of low roadbed and heavy load-bearing for roadbed construction in windy and sandy areas, geocells can be used to limit the loose fill. The roadbed is guaranteed to have high stiffness and strength within a limited height to withstand the load stress of large vehicles.

3.Platform back roadbed filling and reinforcement

The use of geocells can better achieve the purpose of reinforcing the abutment back. Sufficient friction can be generated between the geocells and the filler, which can effectively reduce the uneven settlement between the roadbed and the structure. In the end, the “bridge abutment jump” can be effectively alleviated. “Car” disease causes early impact damage to the bridge deck.

4.Roadbed in permafrost areas

When constructing fill roadbed in permafrost areas, the minimum filling height should be reached to prevent grouting or causing the upper limit of the frozen layer to drop, resulting in excessive settlement of the embankment. The unique facade reinforcement effect and effectively implemented overall confinement of geocells can ensure the minimum fill height in some special areas to the greatest extent, and make the fill have high-quality strength and stiffness.

5. Loess subsidence treatment

When expressways and first-class highways pass through sections of collapsible loess and loess with good compressibility, or when the allowable bearing capacity of the foundation of a high embankment is lower than the pressure of the combined vehicle load and the self-weight of the embankment, the subgrade should also be constructed according to the bearing capacity requirements. When processing, the advantages of geocells will become apparent.

6.Saline soil, expansive soil

Highways, first-class highways, road shoulders and slopes built with saline soil and expanded soil all adopt reinforcement measures. The facade reinforcement effect of the cell is the best among all reinforcement materials, and it has excellent corrosion resistance. It can fully meet the requirements for constructing high-speed roads in saline soil and expansive soil.

Reviews

There are no reviews yet.