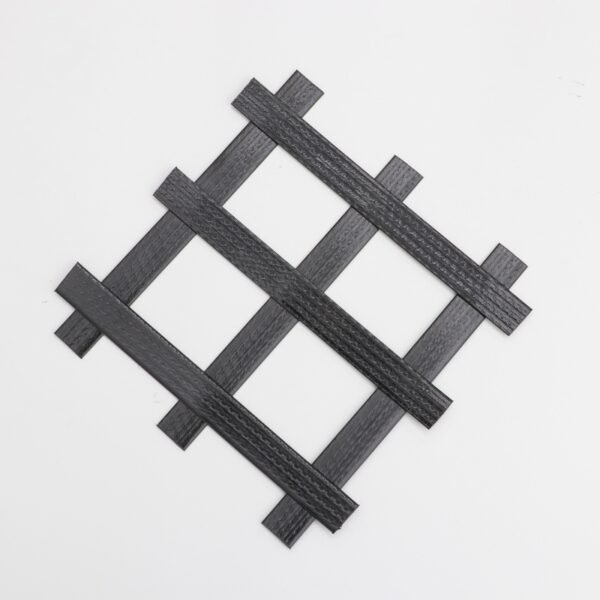

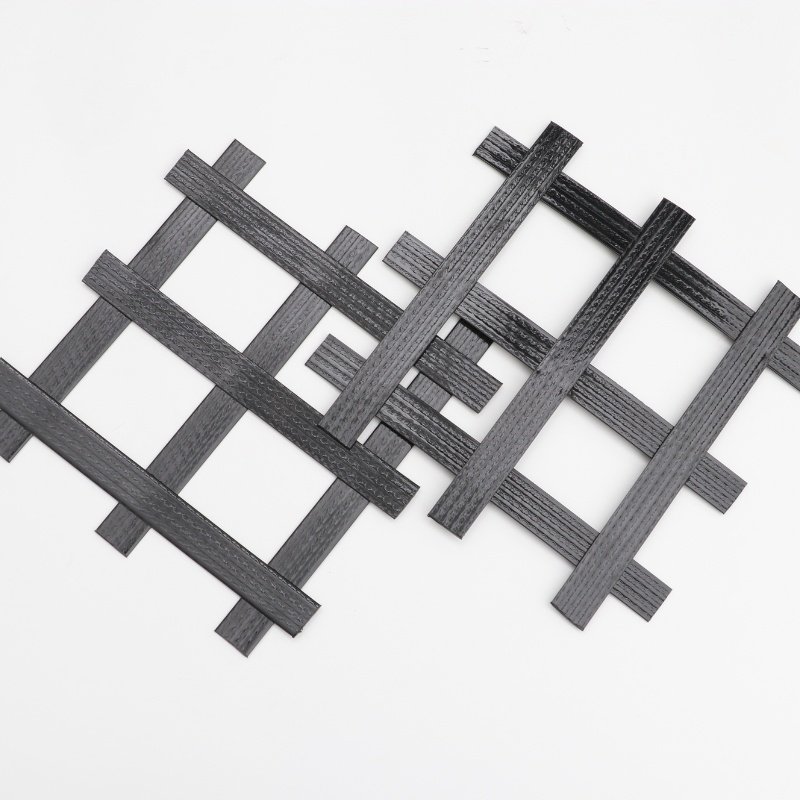

Description Of Welding PET Geogrid

PET polyester biaxially stretched welded geogrid is made of polyester as the main material, adding anti-aging agents and other additives, and is mechanically stretched at low times into refined ribs. The geogrid is formed at right angles according to the longitude and latitude of the plane, and is formed by special ultrasonic welding. Materials, according to project needs, use different mesh diameters, rib widths, and thicknesses to change the tension of the ribs.

Product advantages

1.The tensile force of PET polyester biaxial tensile welded geogrid is borne by the warp and weft woven polyester ribs, which produces extremely high tensile modulus under low strain capacity. The longitudinal and transverse ribs work together to give full play to the grid’s embeddedness in the soil. Lock function.

2.The vertical and horizontal polyester ribs of PET polyester biaxially stretched welded geogrid are woven into a mesh. It has the characteristics of high strength, small elongation at break, and small creep coefficient. The temperature resistance range is -70 degrees Celsius to 180 degrees Celsius. Excellent UV and microbial corrosion properties.

3.Through the treatment of the polyester surface during the production process, rough patterns are pressed to enhance the roughness of the grid surface and improve the friction coefficient between the geogrid and the soil.

4.The width of PET polyester biaxially stretched welded geogrid can reach 6m, achieving efficient and economical reinforcement effect.

5.The PET polyester material used in the PET polyester biaxially stretched welded geogrid can ensure that: it will not be corroded by acid, alkali, salt solution, or oil at normal temperature; it will not be dissolved by water or invaded by microorganisms. At the same time, the polymer properties of polyethylene are sufficient to resist aging caused by ultraviolet radiation. After the grille is stressed, the vertical and horizontal ribs work together to prevent the nodes from being cracked or damaged. In actual projects, after the filler is compacted, it is not corroded by ultraviolet light and oxygen, so it can fully meet the requirements of permanent engineering construction.

Product application

Used for highways, railways, embankments, bridge abutments, construction access roads, docks, revetments, flood control embankments, dams, tidal flat management, cargo yards, slag yards, airports, sports fields, environmentally friendly buildings, soft soil foundation reinforcement, retaining wall reinforcement, high Civil engineering projects such as slope treatment, and water conservancy projects exposed to the outside world.

Construction method

1.The paving surface of the geogrid should be relatively flat. After the paving layer has passed the inspection and acceptance, in order to prevent longitudinal skew, first draw a white line or hanging line on the paving layer according to the width, then start laying, and then use U-shaped nails to fix the grid. The end of the fence (fix it with 4 nails per meter wide and evenly spaced).

2.After fixing the ends of the grating, use a laying machine or manual method to slowly pull the grating forward. Manually straighten it every 10 meters until one roll of grating is laid, and then lay the next roll. Same as before.

3.The unit of roll length is used as the laying section length. After the section length of the grid should be laid, the overall laying quality should be checked again, and then the next section should be laid.

Reviews

There are no reviews yet.